Drafting &

Design

TW

* Some of the material you see was from when I was in school, so please don't judge my skills by old and not yet polished work..

Work Samples:

The President of Netzsch Pumps North America, LLC recently requested I make a 3D video showing how we could replace a competitors pump, this is what I was able to create using Invertor Pro. I could also do something like this utilizing SolidWorks, if that is the 3D program being utilized.

AutoCAD

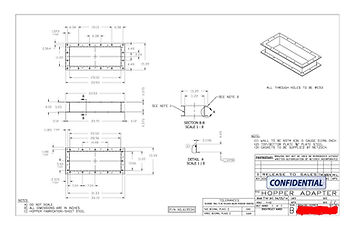

This is a flange transition for a hopper that I designed and drafted for an pump application

at Netzsch Pumps that the customer ultimately approved.

This is a rotary lope pump with a pressure relief valve system I design for a customer. It was sumitted to the customer approved then fabricated.

I made this floor plan along with elevation views in a class project in college. This is only a small sample of my skills in AutoCad and I would enjoy the privilege to show you more if we have a chance to meet.

*This was class work years ago.. I have evolved since then.

Elevation view of the first floor plan above. I had to upload these as JPEG, so the images are a bit distorted.

*This was class work years ago.. I have evolved since then.

Explanation literature in progress; work sample layout is quite a mess at the moment, please come back to see the finished clean "work sample page"

Inventor Pro

This is an display I recently designed and engineeered for Buy Buy Baby corporation. The main top, deck and slat walls are made of MDF melamine with a steel tube structure. The shelving is steel brackets with pre-fab structure and Ven4ma miterfold overlay.

This is a 3D model of an relief valve assembly that I recently designed for a customer at Netzsch Pumps North America, LLC. After designing I converted to 2D dwg and annotated in AutoCAD because we are not yet saving or dimensioning in our 3D program.

This is a 3D model of a piggy back arrangement for Netzsch's tornado pump. I made this for a customer that wanted a model for his warehouse 3D model.

This is a 3D model of Netzsch Pump's competitor I made for a 3D replacement video that I made. I could show you the 3D video on request at an interview.

SolidWorks

This was also done in SolidWorks as an assemply piece. This was a 3D model made for my previous employer to show a client a realistic view of an idea from a sketch. It was really fun making this piece.

Just at home on a weekend wanting to practice my solidworks skills and looked at my lamp and started to draw it. This is the 3D assembly that ultimately came out.

Weldments

WeldMent industrial Couch Frame I recently made for a customer. Also, this model is fully parametrically controlled using equations.

Finished drawing with cut list of the Couch Frame.

HsmWorks - CAM (computer aided manufacturing) I have experience utizing

This is a basic part that I designed, detailed and utilized HsmWorks to create the tool path with feeds and speeds. I wanted to show that I can design a part and follow through with all aspects to machining manufacturing and final product.

Consulting

This is an monitor display enclosure that I did not design, but revised and updated the model, flat pattern and fabrication drawing for submittal to the customer for final approval.

Project flat pattern

Rose Metal Industries

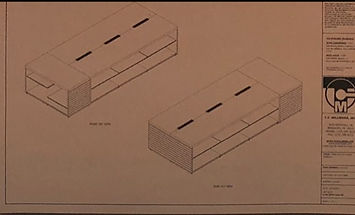

This is a heat treating fixture I designed mostly in SolidWorks and converted it to 2D AutoCAD because my employer at the time only had 1 3D Solidworks license and everyone had AutoCad and/or a 2D viewer, so I took a .jpeg isometric view (as shown in the upper right) and put it on the server, so that anyone that opened it could see everything I put into the XREF path. Pretty much making a drawing that looked like a 3D drawing, but in a DWG format. My boss liked it very much. Also, I wish I could show you there old title block and the updated title block I made for the company.

Silicon Power Corporation

Project I recently worked on for Silicon Power Corp., Nema enclosure with drawers and different electrical components.

See Below 1 of 5 drawer drawings within the engineering packet I did for a customer collaborating with the electrical engineer for placement and spec's to the overall assembly. The customer ultimately approved the design and I did an animation video to show the finished product and functionality.

Drawer drawing for Nema enclosure below. See (Play) video above. My boss gave me all the electrical components laying them out on a table (it was a mess) and said "Tim make all this fit inside this Nema enclosure!

Below is a submittal drawing I did for a concept for Silicon Power Corp. There was potted electrical components inside with anode and cathode connections on the exterior.

Previous work for Netzsch Pumps North America

Progressive cavity pump skid design I did for Netzsch Pumps North America (API 610 base plate). Not being a degreed engineer only having a Associate Degree I appreciate Netzsch for giving me the opportunity to design the first API 610 baseplate from scratch for our customer at the time. Being completely honest I do have to say that my department head and (he was a degreed engineer) did oversee the project and "red line" my drawings all through the design process checking the API design standards throughout the process. But, I made all fabrication notes put in all GD&T datum symbols and tolerances.

I desinged the custom 90 degree flanges that transitioned from a rectangular bolt pattern on the pump to a circular bolt pattern and a specified distance between flange to flange for the customer's needs/request (Center to center of flanges needed to be held and was a critical dimension) I called-out off the shelf 90 elbows and other components to keep cost down.

R&M Equipment Co., Inc

SolidWorks

This is a sound enclosure project I worked on for a previous employer R&M Equipment Company Inc. located in Spring City, Pa. I had to design from scratch a support system for a 500Lb fire suppression system that is all self contained having chemical pressure tanks inside a large Nema enclosure and could not be mounted directly to the sheet metal foam panels, so the custom mount is actually welded to the I-beam at the bottom of the skid. * The final drawing and design is not shown on my computer, if you look close you can see the changes I made, but I took the pictures too early in the design process*

I engineered and designed all the sheet metal ductwork for the pneumatic controlled dampers with mounting that does not hit the floor; you don't see the bracket that is attached to the I-Beam (it is not yet welded on).

Not actual Nema enclosure used on project; for example purposes only; the item used was larger and had the tanks inside.

The 2 Red pressure tanks would be mounted inside of the Nema enclosure above.

Overall floor mounted blower package I designed with all silencers, pressure relief valves and piping.

Revit

Below was a building concept I did in my architectural II class with material costs and schedule timeline. Revit auto-figured after I put in all materials per foot and I made the schedule utilizing Microsoft Project. I ultimately received an A+ for the project.

Capstone Final Project at ITT Technical Institute

This was my capstone project and I did it in Revit Architecture. There is a Revit shot and render of the front of the building. My project was a renovation of our existing school structure. The renovation inclued a four story dorm room addition along with a 3 story parking garage.

Adobe Photo Shop

This was also a project for R&M Equipment Co. They were just starting to sell acoustical wall panels for office space and our salesmen asked how we could show what the panels they chose would look like in their desired space. I took the 2D drawing below of the foam panels made a 3D model of the them with color they wanted to scale converted to a .jpeg of that and put the customer office picture received with the 3D model I made to a .jpeg and put them all together in layers in PhotoShop ( actually GIMP a free program) to make the new photo at the very bottom and the customer loved it and purchased many panels for different boardrooms in their facility. I believe the salesman said my picture made the job worth 40% more and accepted within the hour and they were going back and forth for weeks.